Why Choose Western Core LLC?

High Quality & Strength

We have strict standards on

moisture content and

critical dimensions.

Time Saver

Free up your labor, space,

and inventory so you can

focus on what you do best.

Custom Part Sizes

We provide custom

component sizes to meet

our customers needs.

Our Products

LVL W/ Poplar Edge

Finished Stile W/ Veneer

Stave Core W/ Poplar Edge

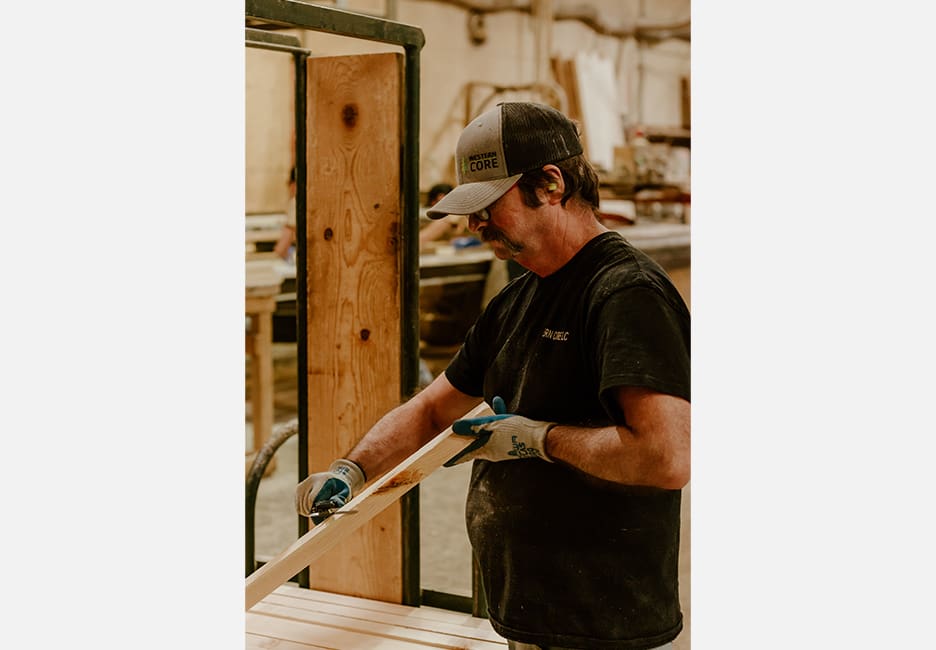

Leading the Way

Since our inception in 1973, Western Core has led the way in stave core construction, pioneering advancements in doors, windows, furniture, and more. Headquartered in Weiser, Idaho, our forest product industry legacy reflects a commitment to refining stave core manufacturing. Recently expanding our portfolio to include laminated veneer lumber (LVL), we continue to evolve with the industry under the leadership of Anthony Bushong. Renowned for our stave core and trusted by major U.S. manufacturers such as Haley Bros and Hardwoods Specialty Products, we take pride in the unwavering support of our customers. Leveraging decades of experience in the forest products industry and refined stave core construction processes, we deliver superior products, swift turnarounds, and steadfast customer support.

Experienced Team

Benefit from the collective expertise of our team, boasting over 100 years of combined experience in the wood and door manufacturing industries. We leverage this knowledge to deliver a superior stave core product, ensuring fast turnaround times and ongoing support for our valued customers. Here are the leaders of our team:

Elevating Industry Standards

At Western Core, dedication to sustainable manufacturing is paramount. We hold our customers, team members, and natural resources in the highest regard, implementing sustainable forestry and manufacturing practices to minimize environmental impact. In our ongoing journey, Western Core steadfastly upholds its dedication to minimizing environmental impact, forging partnerships with sustainable and eco-conscious enterprises, and contributing to the betterment of our global community, encompassing our clientele, team members, and beyond.

Why Choose Us

Premium Quality

At Western Core, our dedication to excellence is evident in every aspect of our stave core production. We meticulously craft our cores from premium ponderosa pine, Douglas fir, and white fir wood, with each step supervised by our expert team. Additionally, our state-of-the-art drying process ensures optimal moisture content, exceeding industry and building standards. This process guarantees the highest quality, resulting in stave cores that are resistant to warping and tailored to meet our customers' precise delivery and production requirements.

Diverse Product Range

Whether you seek high-quality stave cores for doors, windows, or tables, Western Core has a solution. With a diverse array of sizes and wood options, we collaborate with you to find the perfect fit for your business.

COMMITTED TO EXCELLENCE

We prioritize providing top-quality stave lumber core along with exceptional service. Our track record speaks for itself – with no customer complaints, and we have a loyal base of long-term clients, some spanning over four decades.

Who Do We Serve

We serve door manufacturing companies across the United States with quick turnaround times. Our extensive experience includes collaboration with door manufacturers of various scales, fulfilling orders ranging from a few hundred units to multiple truckloads.

Cutting-Edge Innovation

Western Core is a leading stave core supplier in the United States, consistently innovating to maintain our position at the forefront of the industry. Our state-of-the-art stave core drying process ensures optimal moisture content, surpassing industry and building standards. By kiln drying the core after gluing to achieve a moisture content of 6% to 10%, we have successfully eliminated common issues such as warping and telegraphing that were prevalent in the '90s and early 2000s. In response to market demands, we have expanded our product offerings to include laminated veneer lumber (LVL), broadening our capabilities to cater to diverse customer needs.

Strategic Growth

Our strategic growth is reflected in substantial increases in production capacity. Formerly manufacturing three truckloads of stave core per month, we now consistently ship over eight truckloads monthly. Our commitment to fast turnaround times has been a driving force behind our success and customer satisfaction.

How We Help Eco-friendly Manufacturers

We take great pride in our accreditation by the Forest Stewardship Council (FSC), an esteemed organization that establishes the fundamental principles and certifications governing global forest management. This certification underscores our commitment to sourcing stave lumber core products from responsibly managed forests. Aligned with the FSC Principles and Criteria, our operations prioritize the protection of biological diversity, the integrity of forest land, and efficient resource utilization, among other crucial aspects. Our unwavering commitment involves maintaining this certification and continually enhancing our processes, ensuring a greener and healthier future for our forests and the planet.

As California's leading organization overseeing climate change initiatives and pollution control efforts, CARB plays a pivotal role in our operational landscape, given the proximity of many customers. Recognizing the critical importance of protecting air quality and mitigating greenhouse gas emissions, we have implemented substantial measures to align our stave lumber core manufacturing operations with CARB's stringent requirements. Our compliance with these regulations demonstrates our dedication to environmental responsibility and contributes significantly to the collective efforts to combat climate change and safeguard public health.

Our commitment to ecological responsibility in the manufacturing sector extends beyond conventional standards. Western Core is actively championing green manufacturing practices in conjunction with obtaining sustainable manufacturing certifications. The following highlights some initiatives through which we are fostering environmental stewardship and advancing sustainability.

Our waterproof Type 1 Polyvinyl acetate (PVA) glue stands out for being urea-free and qualifies for LEED points, aligning with sustainable and environmentally friendly building initiatives established by the U.S. Green Building Council.

Polyvinyl Acetate (PVA) glue, commonly known as white or school glue, is generally acknowledged as a more environmentally friendly adhesive than solvent-based alternatives. The eco-friendliness of PVA glue hinges on factors such as production, use, and disposal. Our Type 1 PVA glue is safe and biodegradable, making it a sustainable and secure choice.

Urea Formaldehyde Glue, also known as Plastic Resin Glue, historically used in plywood and particleboard, posed respiratory concerns. Moving away from this substance underscores our commitment to safety and environmental responsibility.

In alignment with sustainability goals in the forest products and door manufacturing industries, Western Core addresses waste reduction responsibly. We repurpose low-grade lumber, often discarded in typical building projects, into our high-quality stave core. This transformative process mitigates waste and yields a premium product that surpasses other wood lumber core options.

Beyond waste reduction, Western Core embraces lean manufacturing principles, systematically minimizing waste in various forms, such as overproduction, excess inventory, defects, and time inefficiencies. Our commitment embodies streamlined, efficient, and eco-conscious practices. Optimizing production processes reduces waste and enhances overall productivity for manufacturers.

Reach Out Today

Seeking a reliable stave core supplier? Experience our quality with a free stave core sample. Contact our skilled team for assistance in finding the perfect products for your needs.